Regular engine maintenance is essential for reliable performance of diesel-powered motorhomes, but one area of maintenance commonly overlooked is the diesel tank. A pre-season inspection of tank fittings, seals, and hoses is recommended, but the real issue lies within, and this is water inside the tank.

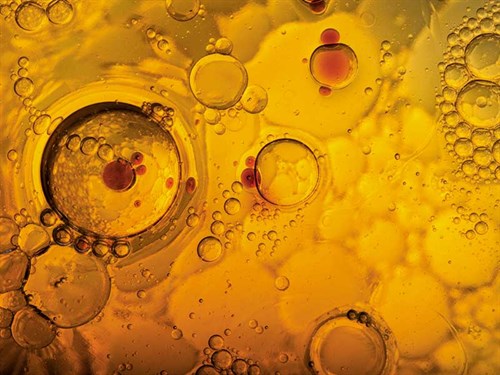

Because water is heavier than diesel, it sinks to the lowest part of the tank and provides the oxygen necessary for the growth of a microbiological organism we commonly refer to as diesel bug.

Diesel bug propagates quickly in warm, humid climates and generates acids that pass through the fuel filters and corrodes the highly polished metal surfaces found on the inside of fuel injection pumps and injectors.

Over time, this corrosion can lead to fuel leakage into the engine’s oil system compromising oil viscosity, thus resulting in crankshaft and/or main bearing failure. Generally, it is not a question of if but when. Words of caution: newer common rail diesel engines are particularly susceptible to damage from water ingress in diesel because of the high volume of fuel returned to the primary diesel tank.

This return flow is warmed by the engine and raises the temperature of diesel in the tank. As the tank cools, condensation forms on the tank walls and settles on the tank floor near the fuel pickup, creating an ideal environment for diesel bug to take hold.

The problem occurs when you start your engine. Water at the pickup can overwhelm primary and secondary filters and enter the fuel pump and injectors. While fuel treatment additives can go some way to preventing the growth of diesel bug, sometimes the only real way to prevent it is by removing its life source—the water.

How does diesel bug infect fuel?

There are up to 30 known microorganisms that can degrade diesel and these predominantly comprise bacteria, yeasts, and fungi. All, however, are airborne. The microorganisms exist in the water molecules that are suspended in the air. It is from the water that these organisms extract enough oxygen to thrive. And because fuel tanks must be vented, this creates a pathway for air and microbes to flow in and out of a diesel tank.

Diesel tanks provide something of a gourmet environment for microbes because, as we know, water is heavier than diesel and sinks to the bottom of a tank and settles on the bottom. This is known as “water bottom”.

Water bottom provides an interface between the water and the fuel effectively allowing microbes to dine at both tables, extracting the oxygen necessary to thrive from the water below while sourcing energy in the form of carbon and nutrients from the diesel above.

When fuel in a diesel tank is warmed due to engine return flow, microbe growth can be extremely rapid. What can typically occur is, as water in the fuel is gradually burnt off it leaves behind a buildup of slimy black sludge on the tank floor which mixes with the diesel.

Water—where and how

The major cause of water ingress in diesel is from condensation, and for this reason, the best defence against diesel bug is to keep you tank topped up. This will go a long way to preventing condensation in the tank because air is unable to be exchanged. And that is simply because there is no air-space present.

Faulty fillers are also a common cause of water ingress into diesel tanks and should be checked regularly. The use of O-ring seals under filler caps is advised to prevent moisture wicking down the threads and into the tank.

How to spot a diesel bug

Diesel bug can have many guises but will predominantly make itself apparent in the form of a slimy black material or grit in diesel filters, tank floors, and other fuel system components. Other telltale signs include pitting and corrosion of fuel system components due to the acids produced during the metabolic process. Fuel colour (darker and more opaque) and fuel smell (hydrogen sulphide) might also indicate that problems exist.

Fixing diesel bug

Once it is in the system, there is only one foolproof way to eradicate diesel bug from your tanks and that is to empty and clean them. This in itself can make the job challenging unless the tank or tanks have inspection ports fitted that provide for internal cleaning.

Biocide treatments for diesel bug

Biocides are often used to treat diesel but these are hazardous chemicals and must be treated as such. Adding biocides can, according to some experts, create problems and expedite the accumulation of sludge on tank floors as it kills off microbes. Ideally, biocides should only be used after diesel tanks have been descaled and cleaned as a preventative rather than a cure. Over time, biocides can also lose their effectiveness as microbes build up immunity to the chemicals.

While more costly, magnetic decontamination and ultraviolet fuel treatment systems are becoming more commonplace and can be effective options for mitigating the risk of

future contamination.

Diesel bug is real and it has to be carefully managed to prevent the real of risk of not just breakdowns but costly engine repairs. The first step is to identify whether you’re infected and to what degree and this will determine what remedial action is required.